“We make the cool stuff!"

From the idea to the perfect product

Process development - Technology & Process Development at Brüggen

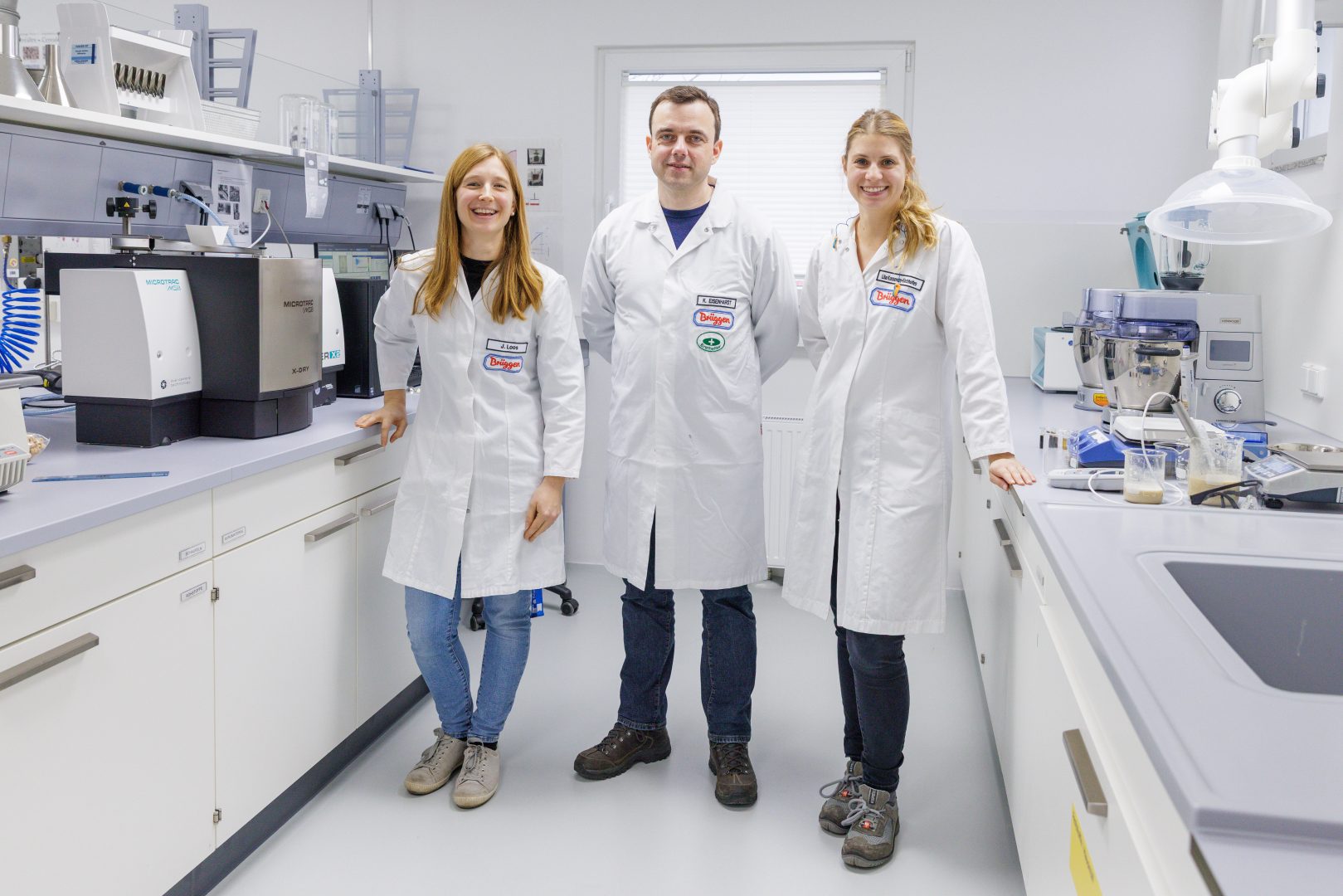

In a small building on Konstinstraße – a former snack bar – the process development team led by Karsten Eisenhardt is working at full speed. Almost inconspicuous next to the large silver production buildings, they work here every day to ensure that our Brüggen products are not only produced efficiently, but also taste great. Find out who the creative minds behind our successful recipes are and what makes their work so special here.

The brains behind the development

Karsten Eisenhardt

Head of department and a real all-rounder: Karsten is a trained master miller and technician with a Bachelor's and Master's degree in food technology. He has been contributing his expertise to Brüggen since 2011.

Julia Loos

Process engineer and deputy head of department. Julia was the first to complete her dual studies in industrial engineering for the food industry at Brüggen. She joined the company in 2010 and has been working in process development since 2015.

Lisa Kossendey-Kirchholtes

Also a process engineer. Lisa studied biotechnology, process engineering and food technology. She already wrote her Master's thesis in Karsten's team, which she has now been a member of for 6.5 years.

The cornerstones of the department

The development activities are based on two central areas.

Technology development: How do substances behave with each other? The team researches this question partly in-house and partly with universities and research institutes.

Process development: This is about how a recipe can be optimally processed – which processes and machines are necessary and which technical requirements need to be created.

Room for creative ideas

A highlight of the department: in addition to fixed projects, there is also room for innovative ideas. The team has already developed innovative concepts – including barbecue charcoal briquettes and oat-based moisturizer as well as its own measuring device for testing the stability of crunchy muesli.

The laboratory: the heart of process development

Originally housed near the works council, it soon became too cramped. When Brüggen took over a vacant snack bar, the team moved in without further ado after extensive modernization. In the beginning, truck drivers occasionally knocked on the door to order a currywurst – now the laboratory is fully equipped with state-of-the-art technology.

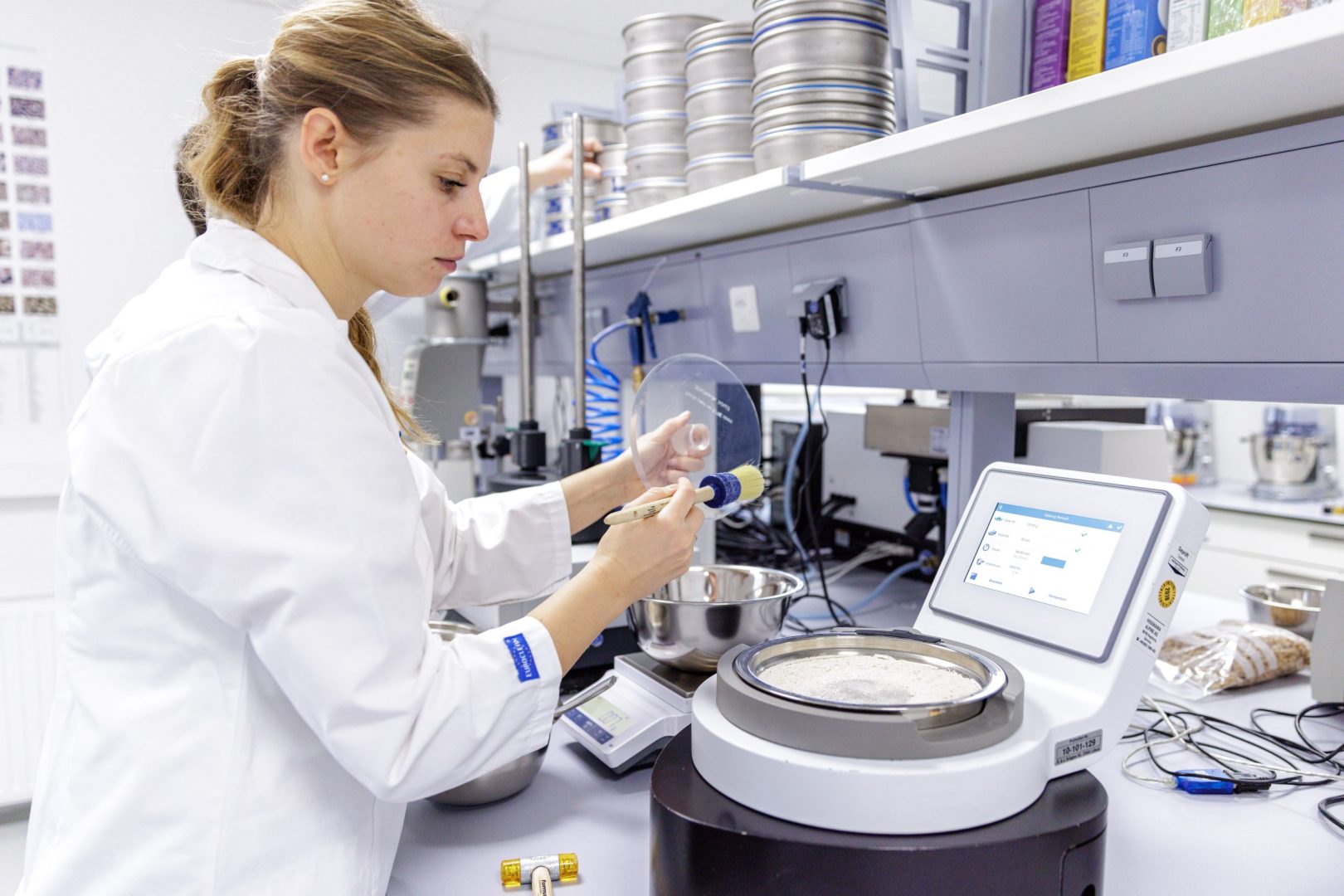

A particular highlight: texture measurement. Here, the consistency of cereals is tested using a press that simulates the chewing apparatus. Everything for the perfect crunch.

Equally exciting is the particle measuring device, which analyzes the finest powder particles with high-speed cameras. It measures structures down to 0.8 µm – that is around one hundred times thinner than a human hair.

Another important instrument is the air jet sieve, which precisely weighs and separates even the finest powders.

Karsten jokes: “But the most important piece of equipment is the coffee machine. It is tested intensively every day, but the final result is still pending.”

Successful project:

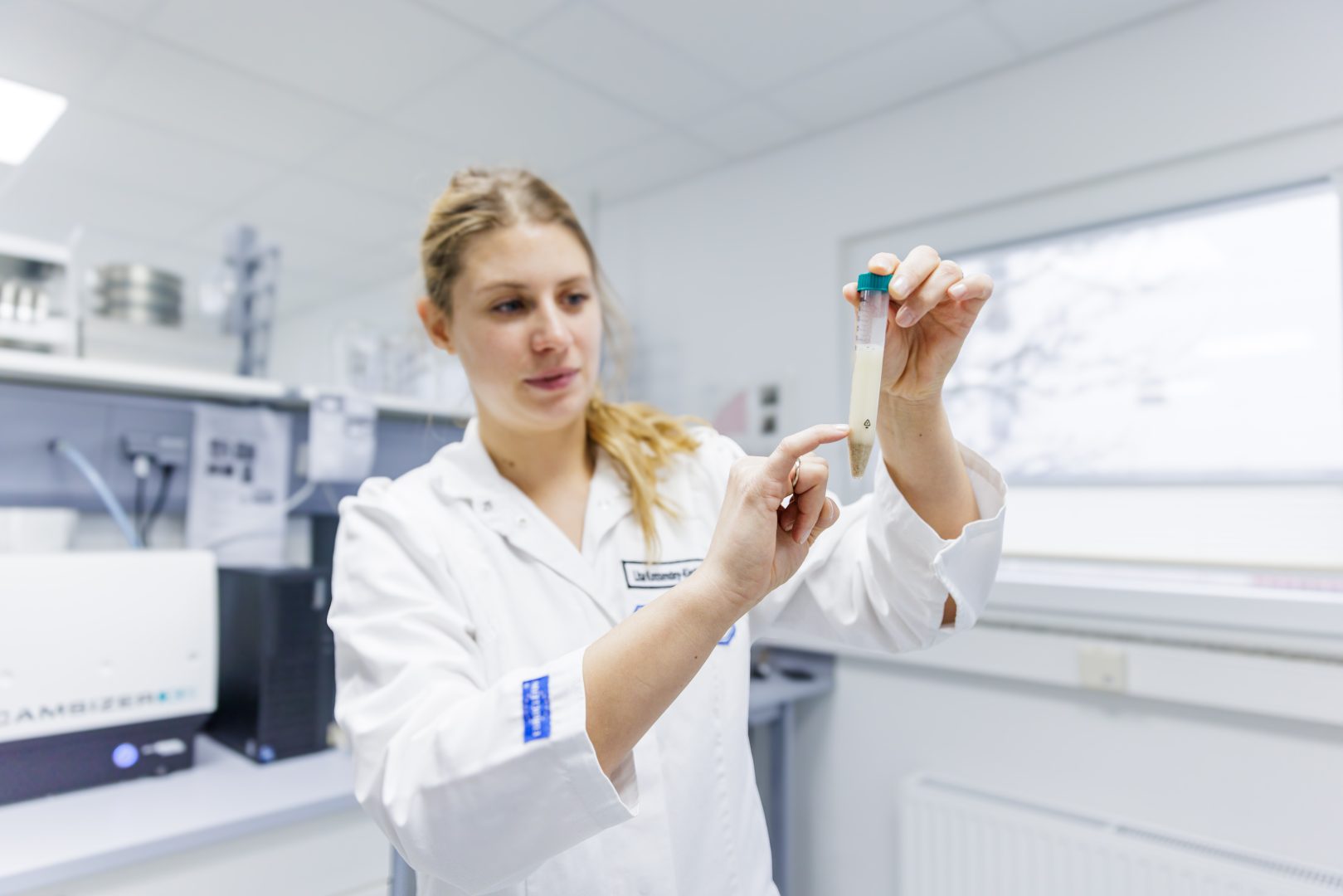

Oat drink with frischli

The development of a high-quality oat drink in cooperation with the dairy frischli was a particularly successful project. Julia and Lisa show us the basics of oat drink production: oat flour is stirred in hot water until a viscous mass is formed. Enzymes then control the consistency and taste. It sounds simple, but it requires precise calculations and countless tastings – because in the end it’s the taste that counts.

Small house, big impact

Despite its modest size, process development makes a major contribution to Brüggen’s success. With scientific know-how, innovative strength and a constant drive for optimization, Karsten, Julia and Lisa ensure that Brüggen not only perfects existing products, but also constantly inspires with new, surprising ideas.

So, the next time you enjoy your Brüggen breakfast, remember: behind every cereal, every piece of muesli and every oat flake is a lot of work that you may not see, but is guaranteed to taste!